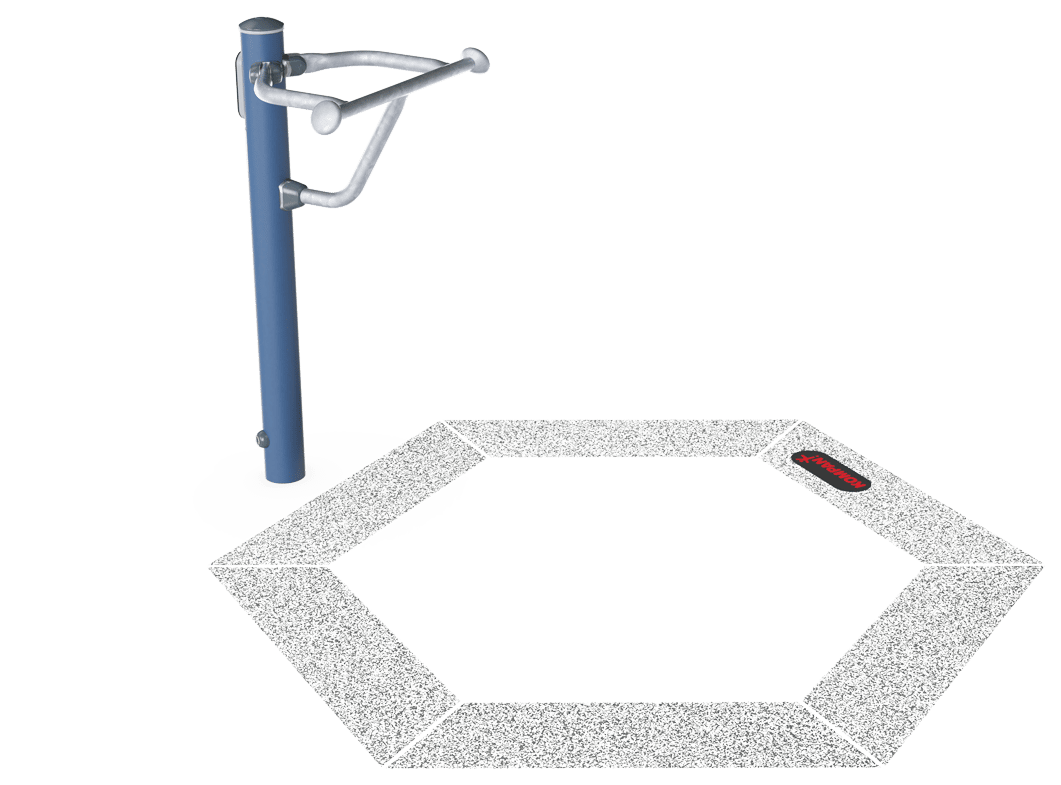

Over the past 10 years, jumping fitness has become increasingly popular. And the reason for this is quite simple. It is tremendous fun, quickly builds up sweat and gives the body a good workout. Jumping on a bouncing element and using our imigination to do different jumps is mentally liberating and something we all can do. The fun keeps us motivated and entertained and positively drives us to being active for longer time slots. The handlebars offer support for beginners and adds the possibility to do high intensity power rounds with extra high jumps.

사진은 컨셉 참고용으로 실제와 다를 수 있습니다.

길이

192 cm

너비

188 cm

높이

117 cm

사양

Over the past 10 years, jumping fitness has become increasingly popular. And the reason for this is quite simple. It is tremendous fun, quickly builds up sweat and gives the body a good workout. Jumping on a bouncing element and using our imigination to do different jumps is mentally liberating and something we all can do. The fun keeps us motivated and entertained and positively drives us to being active for longer time slots. The handlebars offer support for beginners and adds the possibility to do high intensity power rounds with extra high jumps.

본 제품 Fitness Jumper (FSW232)은 KOMPAN 대한민국에서 제공합니다.

오래 지속되는 품질

The jumping membranes are made of 6,0mm thick EP Ethylene-Propylene conveyor belt with polyester polyamide fabric carcass. Spring fixations are reinforced with steel bushings and washers on both sides. The membrane is ozone resistant and equipped with 8 center placed water drain holes.

All 36 springs are made of stainless steel to ensure durability and excellent corrosion resistance. The steel wire is 3,2 mm thick and the last five windings are cone shaped to ensure long lifetime of the jumper.

The tiles are molded in grey granulated recycled rubber (SBR/NR), and the KOMPAN logo is made of EPDM Ethylene Propylene Diene Monomer. Inside each of the rubber tiles there is a 3 mm hot dip galvanized steel plate.

All steel components are manufactured from carbon steel S235 in a thickness of 3 mm. Side panels, support walls for top frame, plates bended with SBR and plates flat for in-situ surfacing are hot dip galvanized.

As a unique feature the SBR tiles can be removed for cleaning and service. By loosen six screws the SBR tile can be lifted up to open and gain access to the springs (see instruction on KOMPAN Master).

The support handle is 530mm wide. The handle is 1050mm above ground level, and 1140mm above the jumper membrane. The handle is made from an Ø32mm HDG bar.

CO₂ 배출량

Sustainability Data

KOMPAN의 제품 및 지속 가능성 데이터 검증은 고객이 Bureau Veritas가 검증한 방법을 기반으로 정보에 입각한 지속 가능한 구매 선택을 할 수 있도록 지원합니다.

FSW23200-0902

729.52

총 CO₂ 배출량(kg CO₂e)

3.6

CO₂e/kg (kg CO₂e/kg)

60.5%

재활용 소재

입찰 사양서

입찰 사양서 문의

사양 작성을 위한 상세한 자료를 찾고 계신가요? 여러분에게 필요한 모든 문서를 제공합니다. 양식을 작성해 주시면, 관련 정보를 제공해 드리겠습니다.

문의하기

특정 제품 및 프로젝트 문의하기