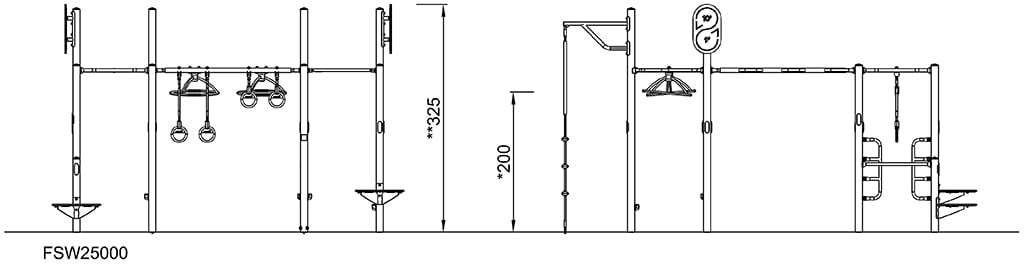

The Super Combi 3 is based on 360-degree activities in a square structure. It has a built-in challenge where you can move from the overhead ladder through the Turbo wheels and end in the snake bar. In addition to this, it has a low bar, incline press, target shoot, climbing ropes, rings, and jumping platforms. A very engaging outdoor gym with a compact footprint compared to the many included activities. Ideal for schools and most types of public areas.

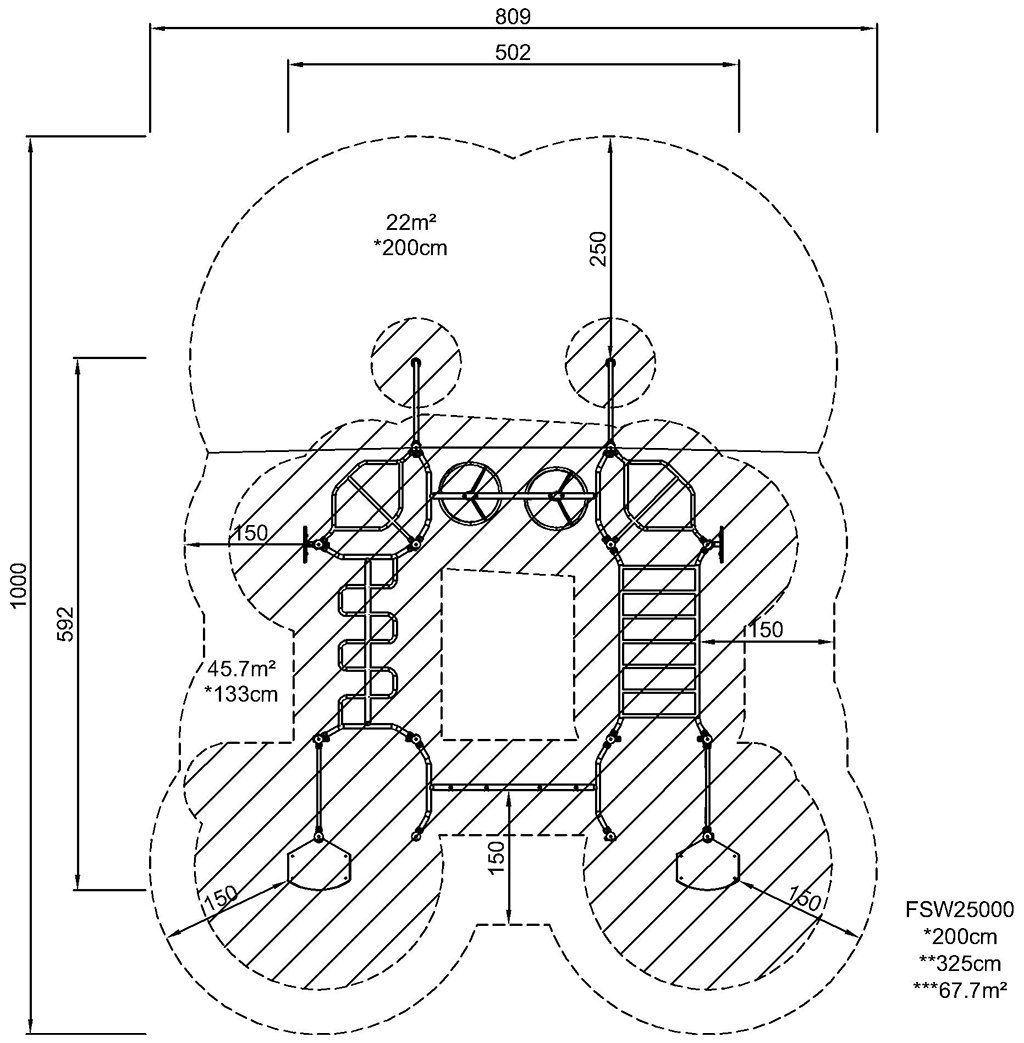

Length

502 cm

Width

592 cm

Height

325 cm

Specifications

The Super Combi 3 is based on 360-degree activities in a square structure. It has a built-in challenge where you can move from the overhead ladder through the Turbo wheels and end in the snake bar. In addition to this, it has a low bar, incline press, target shoot, climbing ropes, rings, and jumping platforms. A very engaging outdoor gym with a compact footprint compared to the many included activities. Ideal for schools and most types of public areas.

This product, Super Combi 3 (FSW250), is provided by KOMPAN United Kingdom.

Quality that lasts

Post are made of Ø101.6 x 2mm, pre-galvanized carbon steel and powder coated, a great protection to all conditions.

The snake ladder is made of hot-dip galvanized s235 steel with the following dimensions Ø38 x 4mm. The steel surfaces are hot dip galvanised inside and outside with lead free zinc. The galvanisation has excellent corrosion resistance in outside environments and requires low maintenance.

The rings are made of molded polycarbonate and TPE to ensure a good grip and soft surface. The rings are rotatable and allows for a large variety of exercises.

The top plate for the jumping platform is made of Ekogrip® panels that consist of a 15 mm polyethylene bottom layer, with a 3 mm top-layer of thermoplastic rubber with a non-skid effect for safe jumping exercises under all-weather circumstances.

The plate for the target is made from 19mm EcoCore™ HDPE that consists of +95% recycled post-consumer material from e.g., food packing waste in both core and colorful outer layer.

Overhead Turbo Challenge have a base of hot dip galvanisation and a powder coated top finish. This provides an ultimate corrosion resistance in all climates around the world.

CO₂ emission

Our product and sustainability data validation help customers make informed sustainable buying choices based on methods validated by Bureau Veritas.

FSW25000-0901

1293.97

Total CO₂ emission (kg CO₂e)

2.32

CO₂e/kg (kg CO₂e/kg)

58.76%

Recycled materials

The overall framework applied for these factors is the Environmental Product Declaration (EPD), which quantifies "environmental information on the life cycle of a product and enable comparisons between products fulfilling the same function" (ISO, 2006). This follows the structure and applies a Life-Cycle Assessment approach to the entire Product stage from raw material through manufacturing (A1-A3).

TENDER TEXT SPECIFICATIONS

Looking for tender specification texts?

Do you want to include this specific product in your project, and are you looking for detailed material information to help you specify? We have all the documentation you need. Fill out this form, and we will contact you with the relevant information you need.

How can we help you?

If you have any questions regarding this specific product or your project, we are here to help!