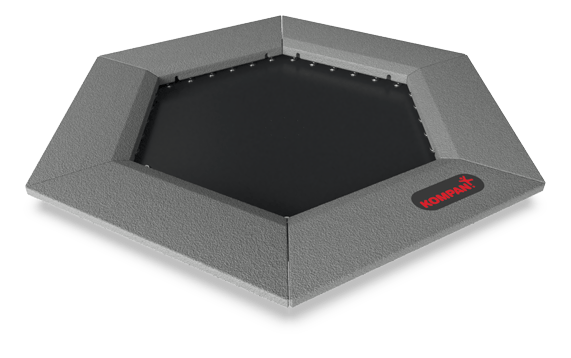

Bouncy floor

体を動かすあそび

trains motor skills ABC: agility, balance and coordination, as well as proprioception and rhythm when jumping on and off. Bone density is built when jumping on and off.

社会情動的スキルを高めるあそび

turn-taking and cooperation skills when timing when to jump in and out, one after the other.