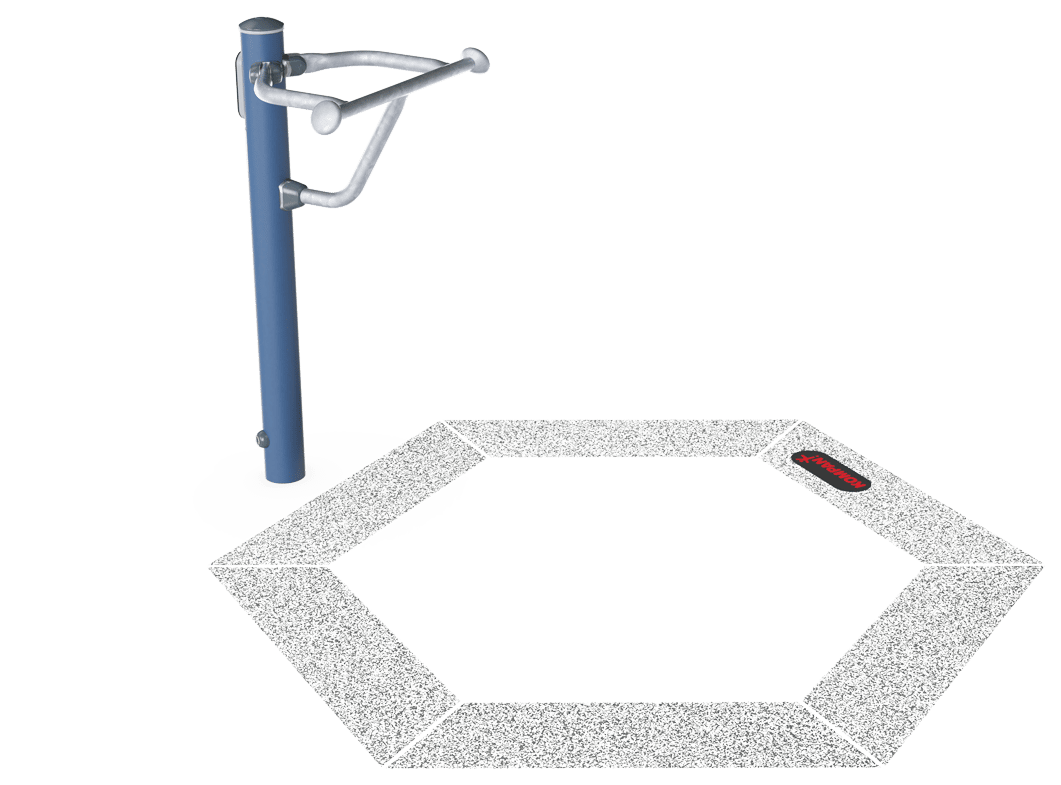

ここ10年ほど、ジャンピングフィットネスの人気が高まっています。その理由は至って単純で、とても楽しく、すぐに汗をかいて体を効果的に鍛えられるからです。跳躍器具の上では、だれでも創造性を駆使してさまざまなジャンプをし解放感を味わうことができます。楽しさはモチベーションやエンターテイメント性を高め、より長い時間エクササイズを行う原動力となります。サポートになるハンドルバーが付属しているため、初心者でも高いジャンプを伴う高強度のエクササイズに挑戦することが可能です。

画像はイメージです。実際の製品は、デザインや仕様が異なる場合があります。

長さ

192 cm

幅

188 cm

高さ

117 cm

仕様

ここ10年ほど、ジャンピングフィットネスの人気が高まっています。その理由は至って単純で、とても楽しく、すぐに汗をかいて体を効果的に鍛えられるからです。跳躍器具の上では、だれでも創造性を駆使してさまざまなジャンプをし解放感を味わうことができます。楽しさはモチベーションやエンターテイメント性を高め、より長い時間エクササイズを行う原動力となります。サポートになるハンドルバーが付属しているため、初心者でも高いジャンプを伴う高強度のエクササイズに挑戦することが可能です。

Fitness Jumper (FSW232)は、KOMPAN 日本が提供します。

優れた耐久性

ジャンピングメンブレンは、厚さ6mmのEPエチレンプロピレンコンベアベルトでできており、ポリエステルポリアミド製のファブリックが骨組みになっています。バネ固定部は、両側のスチール製軸受け筒とワッシャーで補強されています。メンブレンは耐オゾン性があり、中央に8つの排水穴が設けられています。

36本のバネはすべてステンレススチール製で、耐久性と優れた耐腐食性を確保しています。スチールワイヤーの太さは3.2mmで、両側の5巻きを円錐形にすることで、ジャンパーの製品寿命を長くしています。

タイルはグレーの粒状リサイクルゴム(SBR/NR)で成形されており、コンパンのロゴはEPDM(エチレンプロピレンジエンモノマー)でつくられています。各ゴムタイルの内側には、厚さ3mmの溶融亜鉛メッキ鋼板が入っています。

すべてのスチール部品は3mm厚の炭素鋼S235で製造されています。側面パネル、上部フレームのサポートウォール、SBR(スチレンブタジエンゴム)と共に曲げ加工されたプレート、現場仕上げ用の平板には溶融亜鉛メッキが施されています。

SBRタイルは清掃や点検のために取り外すことができます。6本のネジを緩めることでSBRタイルを持ち上げて開き、バネをメンテナンスすることが可能です(KOMPAN Masterの説明書を参照)。

サポートハンドルの幅は530mmで、地上から1050mm、メンブレンからは1140mmの高さにあります。直径32mmで、溶融亜鉛メッキ(HDG)が施されています。

CO₂排出量

サステナビリティデータ

コンパン製品の環境データは、第三者機関であるビューローベリタスによって検証されています。だれでも必要な情報を参照することができ、環境に優しい製品を選ぶことができます。

FSW23200-0902

729.52

二酸化炭素の排出総量(単位:kg)

3.6

二酸化炭素排出量(単位:kg)

60.5%

リサイクル材利用率

TENDER TEXT SPECIFICATIONS

Looking for tender specification texts?

Do you want to include this specific product in your project, and are you looking for detailed material information to help you specify? We have all the documentation you need. Fill out this form, and we will contact you with the relevant information you need.

製品に関するお問い合わせ

製品に関するお問い合わせはこちらからお願いいたします。